Tire Examination

Need to speak to an engineer? Contact our team today.

The Kilpatrick Group, PA provides Tire Examination services to determine if a tire failure occurred and what tire and rim damages exist.

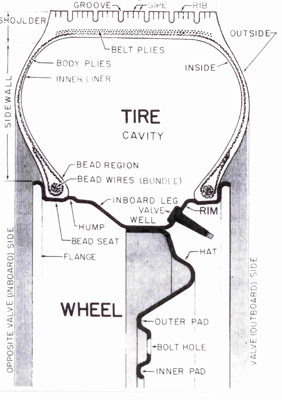

Historically, there are three basic tire designs that have been utilized by the automotive industry to date: (1) the Radial Tire, (2) the Bias Tire and (3) the Bias Belted Tire. The Radial Tire is currently preferred by the United States automotive market. The Radial Tire get its name from the orientation of its body ply strands which are oriented circumferentially or radially around the cross-section of the tire body from one bead region to the other. The Bias Tire gets its name from the orientation of its body ply strands which are oriented on an angle or bias from one bead region to the other. As one layer of body ply strands are laid over the other, the angle or bias of the strands are reversed creating a crisscross or “X” configuration. The Bias Belted Tire is a mixture or hybrid of the Radial and Bias Tire designs. See the image to the left for a cross-sectional view of a basic tire-rim assembly.

The figure to the left is provided here and was approved for display by Northwestern University Center for Public Safety from Their Accident Reconstruction Manual Volume 2 Copyright 1990

A tire can fail for any number of reasons:

A tire that has been inflated to too high of an air pressure.

A tire with low air pressure than is specified by the vehicle manufacturer.

A tire that has aged and has deteriorated due to being exposed to long term outside ambient atmospheric conditions and has dry rot.

When the tire is forced to carry a higher load than what its load rating specifies.

When the tire is operated at vehicle speeds higher than its maximum design speed.

A tire that has design or manufacturing defects.

The tire is old when purchased new from a retailer and displays an old DOT manufacturer’s date code.

When a new set of tires are purchased for a vehicle, the tire’s DOT date code should be inspected before the tire are installed onto the vehicle. This code incorporates the date of manufacture located in the last four digits. The DOT code is located on the sidewall of the tire and begins with the capital letters “DOT”. For example, if the last four numbers of a tire’s DOT code is 4407, this means that the tire was manufactured during the 44th week of 2007. Occasionally after a tire is manufactured, it may sit around in a warehouse for years before it is shipped out to a retailer to be sold. If a tire is several years old when it is purchased new, it could fail in service prematurely because of deterioration due to aging. If the tire fails in service, this failure could be catastrophic where the tire can rupture suddenly. If the vehicle is traveling at interstate speeds during the sudden rupture, this could cause a vehicle to go out of control causing an accident.